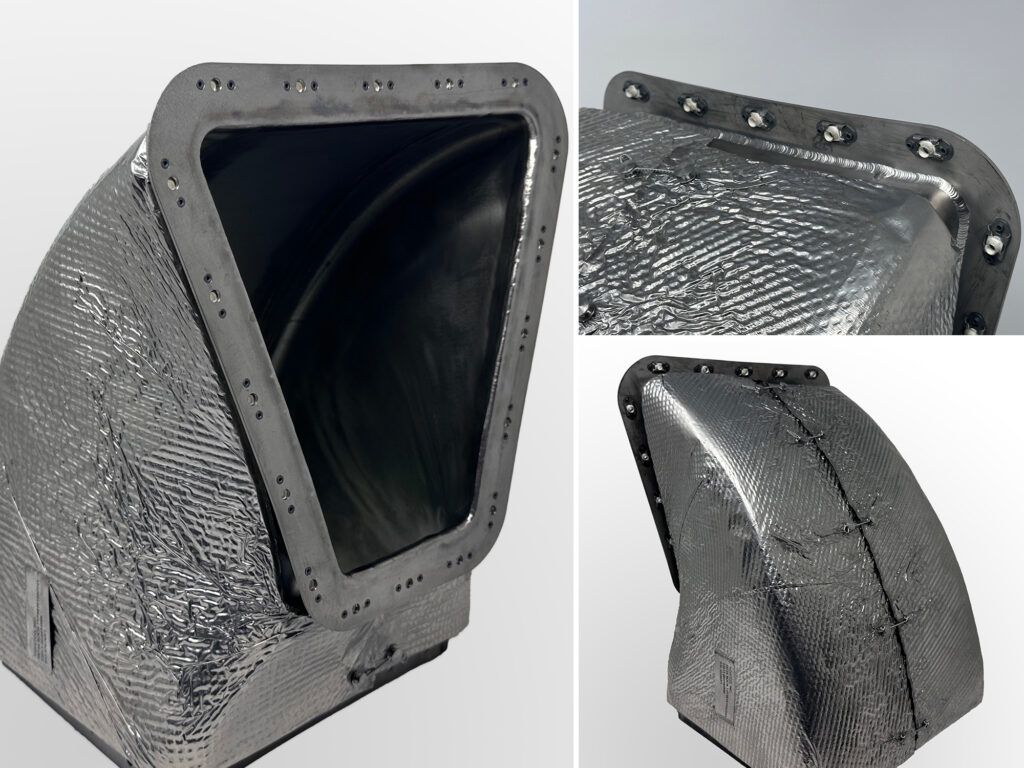

Overcoming Challenges in Fabricating Aerospace Components

In the aerospace industry, safety and performance are non-negotiable. This drives the demand for precise, reliable aerospace components. Aircraft must withstand extreme conditions, from high pressures to rapid temperature changes, while maintaining functionality. The slightest deviation in a part’s design or performance can lead to costly failures or safety risks.

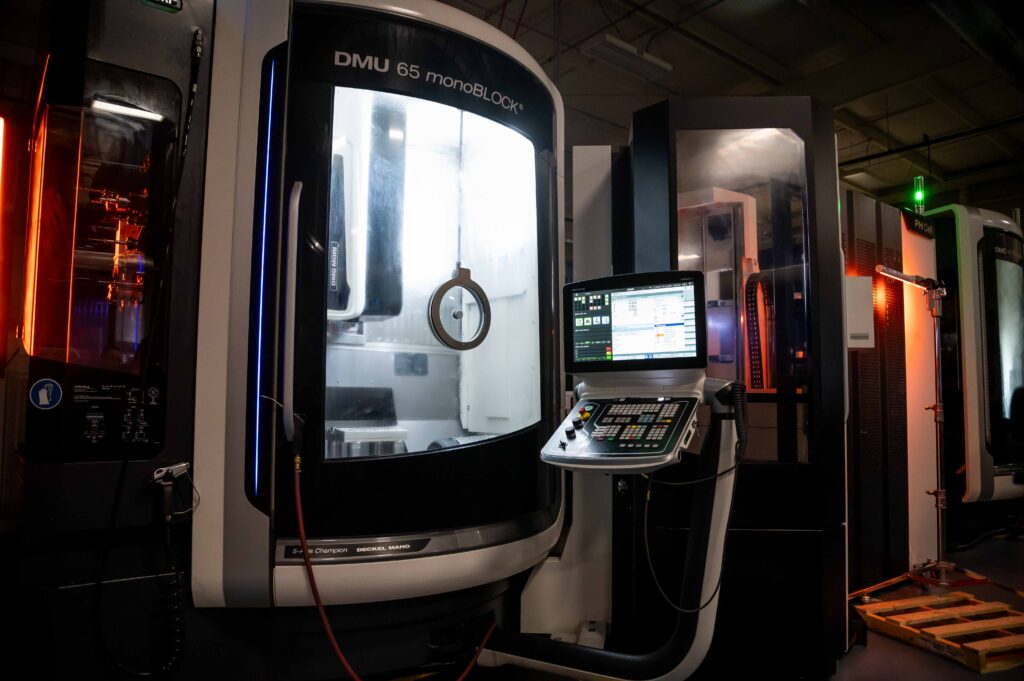

Aerospace Manufacturing Tolerances: Meeting and Exceeding Industry Standards

In the aerospace industry, precision isn’t just measured in millimeters — it’s measured in microns. Manufacturing tolerances for aerospace components demand unprecedented accuracy, where deviations smaller than a human hair can impact performance and safety.

Verifying Quality in the Aerospace Industry: From Testing to Documentation

Achieving high quality in the aerospace industry isn’t just a goal — it’s an absolute requirement. Every component that goes into an aircraft or spacecraft must meet specific standards for safety, reliability, and performance.

A Guide to Metals Used in Spacecraft to Withstand High Temperatures

As technology advances, the demands of the aerospace industry continue to evolve. This is especially true for spacecraft. In the past, spacecraft have been reserved for scientific research and government-backed initiatives.

How to Reduce Lead Time in Manufacturing with the Right Partnership

Lead times impact nearly every aspect of your business, from production planning and scheduling to time-to-market and profit margins. If you’re wondering how to reduce lead times in manufacturing, you’re not alone. The steps involved can be complex. That’s why it’s important to partner with a manufacturer who can coordinate with you to optimize your production.

The Role of Precision Machined Metal Parts in Aerospace Applications

In today’s manufacturing landscape, precision machined metal parts play a vital role, particularly in sectors with strict standards and complex designs. This is especially true in aerospace, where safety, performance, and reliability are of utmost importance.

What Are Chemical Agent Resistant Coatings (CARCs) and Why Do They Matter?

In aerospace and defense manufacturing, protecting critical components from environmental and chemical threats is crucial. One effective way to improve this level of protection is through Chemical Agent Resistant Coatings (CARCs). These specialized coatings are designed to shield aerospace and defense assets from chemical warfare agents, corrosion, and other harsh conditions.

Cybersecurity Compliance: A Key Differentiator for Aerospace Manufacturers

Cybersecurity has become a vital component of operational excellence for manufacturers across the spectrum. With sensitive technologies, defense-related projects, and global supply chains at stake, aerospace manufacturers must prioritize securing their digital environments.

The Strategic Choice of Titanium in the Aerospace Industry

In the aerospace industry, the demand for materials that can meet stringent performance requirements is ever-growing. Among the many materials used in the construction of aircraft and spacecraft, titanium stands out as a preferred choice. Its unique combination of properties makes it indispensable for the production of critical aerospace components.

Understanding Thermoplastic Composites in Aerospace Manufacturing

The aerospace industry is constantly evolving, driven by the need for lighter, stronger, and more cost-effective materials. One such material that has gained significant traction is thermoplastic composites. These advanced materials are playing a critical role in modern aerospace manufacturing, offering a combination of benefits that make them indispensable for the next generation of aircraft.