Cutting Dynamics began in 1985 with three employees and two wire EDM machines on Cleveland’s west side. Since then, we have grown to 200 employees working in a facility of 165,000 square feet by staying ahead of the technology curve and being first to market. In 1987, we established one of the first laser cutting operations in North America, and in 2008 we opened our new hydroforming fluid cell processing center. In 2021, we joined Re:Build Manufacturing, a relationship that has resulted in additional capital investments, further building our team and technology.

Terms and Conditions

To access our terms and conditions, click here.

Backed by our decades of experience, we have developed custom solutions tailored to meet the unique needs of various industries. We understand that each sector has its own set of challenges and requirements, which is why we leverage our extensive knowledge and skills to deliver innovative solutions that drive success.

We create components for passenger aircraft, with capabilities to fulfill high volumes, meet strict standards, provide advanced techniques and materials, and use high-quality processes to produce safe and reliable parts.

Our team is experienced and adept at working with representatives from the defense industry, crafting the vital components they need to maintain the highest standards in safety and functionality. Additionally, we are ITAR compliant.

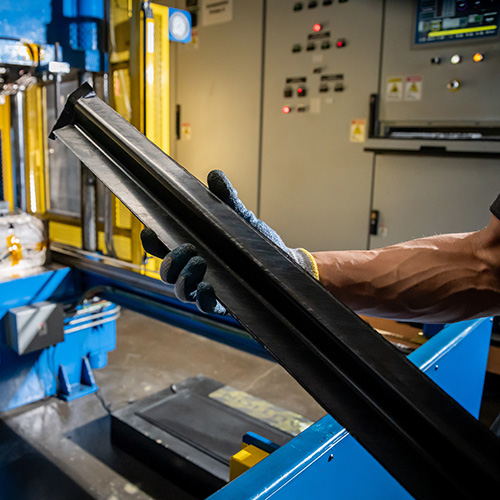

The exceptional skill of our staff allows us to diversify across many different industries, including industrial. Examples of industrial products we’ve made include components for robotics, factory automation, and plasma cutters.

We began in a small shop with one machine making wheelchair components, since then we have expanded our work to include components for blood chemistry analyzers, oxygen compressors, and clinical therapy instruments.

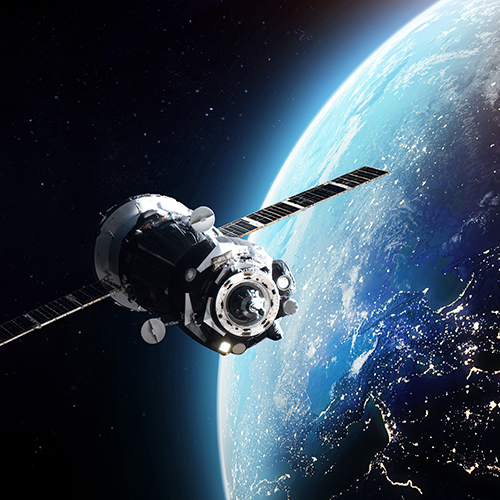

We specialize in the fabrication and assembly of a wide array of components and systems suitable for space and satellite applications. By leveraging our collective expertise and resources, we are able to develop innovative solutions that meet a variety of mission-critical needs.

Our blog features a variety of posts dedicated to highlighting our experience and commitment to being ahead of the curve in aerospace technology. Our blog posts highlight our versatility and capability as an aerospace parts manufacturer.