October 10, 2024

In today’s manufacturing landscape, precision machined metal parts play a vital role, particularly in sectors with strict standards and complex designs. This is especially true in aerospace, where safety, performance, and reliability are of utmost importance. Precision machining enables the production of intricate metal components with micron-level tolerances, ensuring that aerospace systems operate seamlessly, even under extreme conditions.

The aerospace sector depends on high-performance components — such as turbine blades and landing gear — where even minor deviations can affect performance. With recent advancements in precision machining, manufacturers can now produce parts that consistently meet the industry’s rigorous quality standards, driving aerospace technology to new levels.

Wide Range of Capabilities, Precision Results: Connect with our team today to discuss your next aerospace manufacturing project.

The importance of precision machined metal parts in aerospace cannot be overstated. Aircraft and spacecraft operate under some of the most extreme conditions imaginable, from constant wear and tear and intense internal heat, to pressure from high-altitude flight and extremely cold external temperatures. Facing these pressures, even a slight flaw in a given component can lead to disastrous failure. Precision machining helps ensure that each aerospace part meets the tight tolerances necessary for optimal performance, reliability, and safety.

Some of the many precision machined metal parts in aerospace include:

By delivering high-precision parts, aerospace manufacturers can trust that every component will perform optimally, contributing to safer and more efficient flights.

Precision machined metal parts offer several advantages that directly contribute to the success and advancement of aerospace technologies:

Precision machined metal components are essential for optimizing aerospace system performance. Parts like turbine blades, which maximize thrust, and streamlined structural elements that reduce drag, rely on meticulous manufacturing to function precisely as intended. This precision boosts overall system efficiency, allowing aerospace engineers to design high-performance aircraft with improved speed, fuel efficiency, and aerodynamics.

Reliability in aerospace is a strict requirement. Precision machined metal parts meet rigorous quality standards, significantly reducing the risk of failure in critical systems. This reliability allows engineers to innovate confidently, pushing design boundaries while adhering to essential safety and regulatory standards.

While precision machining involves upfront costs, it often leads to significant long-term savings. By minimizing waste and reducing the need for rework, aerospace manufacturers can control production costs while ensuring quality across high-volume runs. These cost efficiencies enable reinvestment in research and development, advancing next-generation aerospace technologies.

Aerospace often demands highly customized solutions, and precision machining enables the production of specialized components tailored to unique applications. This flexibility encourages engineers to experiment with new designs and materials, paving the way for transformative advancements in aerospace technology.

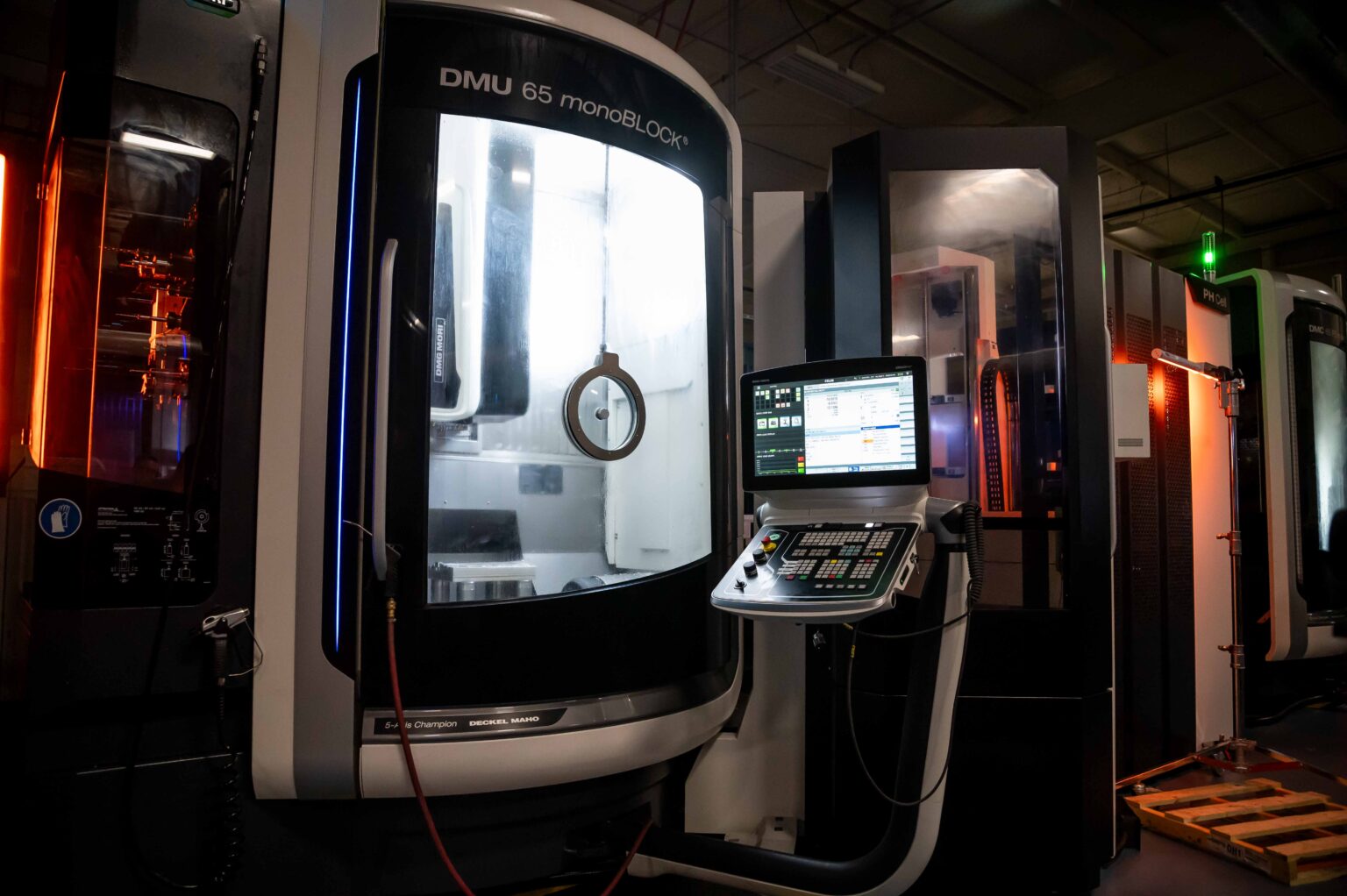

Manufacturing precision machined metal parts presents a unique set of challenges; addressing them requires advanced technology, expertise, and meticulous attention to detail. For instance, aerospace components need to be machined to incredibly tight tolerances, sometimes within microns. Any deviation can compromise system performance and safety. To overcome this, manufacturers use cutting-edge CNC machines, real-time monitoring, and advanced measurement techniques to maintain consistency across production.

Many aerospace components also have intricate shapes that are difficult to machine, such as turbine blades or some structural components. With 5-axis CNC machining and advanced CAD/CAM software, manufacturers can machine even the most complicated designs while maintaining high precision.

By taking on these challenges with advanced technology and expert craftsmanship, manufacturers can produce high-precision aerospace components that meet the industry’s demanding standards for quality and performance.

For decades, Re:Build Cutting Dynamics has been a trusted partner for the aerospace industry, providing precision metal fabrication, CNC machining services, hydroforming, hot forming titanium services, and much more that meet the highest standards. Our experienced team delivers reliable, high-performance solutions tailored to the demanding needs of aerospace applications.

Contact us today to learn how we can support your next aerospace project.

Our team at Re:Build Cutting Dynamics wants to ensure that all your questions regarding precision machined metal parts for aerospace manufacturing have been answered. With that in mind, feel free to contact us today with any questions you may have, as we look forward to assisting you.